Whether you have upcoming new developments or are looking to enhance existing construction projects with wildlife habitat, you may have come across the term ‘woodcrete’, ‘woodstone’, or a variation of the name. This hardy material is commonly used in bird and bat boxes and is often favoured for its longevity and cost-effectiveness. Here we take a closer look at woodcrete, its properties and manufacturing to help you make informed decisions when beginning new construction projects.

What is woodcrete?

Originally patented by Durisol and developed for the construction industry, woodcrete is a building material composed of cement, wood fibres and water. The material is referred to by a number of names, though they are almost identical in composition – woodstone is a trademark registered by Vivara Pro and woodconcrete is the term used by Schwegler, Faunus and Unitura, all suppliers of woodcrete bird and bat habitats.

Woodcrete Properties

A long-lasting, durable material, woodcrete can last for decades. It is weather resistant, does not support fungal growth and unlike wood products, does not rot. It does not leak, warp or crack, making it the ideal long-lasting, secure material for wildlife habitats.

- The breathability of the material reduces the risk of issues with condensation, helping to maintain a healthy environment for roosting inhabitants.

- It has good insulative properties and creates a stable environment inside the box to shelter inhabitants from extreme temperatures – especially important for maternity boxes where young are resting.

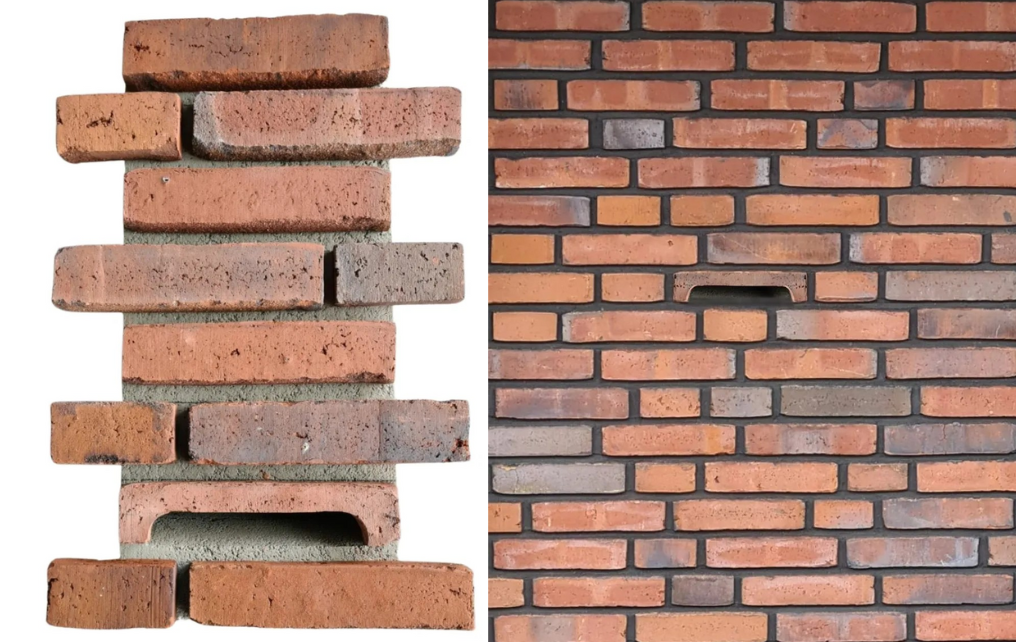

More lightweight than concrete, with great durability and strength, this material is suitable for both built-in and mounted nest boxes. The rough inner surfaces provide texture for bats to cling to, and create a safer, more natural environment for nesting animals. Built-in boxes can also be incorporated into brickwork and can be rendered over to blend into the structure whilst providing habitat benefits for local wildlife.

Woodcrete Applications

Woodcrete is used as a construction material, as well as a variety of building and garden products, including artificial habitat products to support wildlife. These can include bat boxes, bird boxes, insect hides, bee bricks and hedgehog domes. Most commonly, woodcrete bat and bird boxes are available in built-in forms that are installed directly into the walls during the construction of new developments. These boxes are designed to cater to species subjected to habitat loss resulting from the development project itself, or urbanisation in the general area.

Manufacturing process

The material is made by chipping specially graded recycled waste wood and mineralising the chips to neutralise sugars. The chip is mixed with cement and water to create the woodcrete mixture, before being poured into moulds like regular concrete. These moulds are cured at high temperatures to ensure strength and weather-resistance and can take a considerable amount of time for the full curing process to take place.

The manufacturing of woodcrete products is a lengthy process which can cause longer lead times. We recommended ordering any woodcrete product as far in advance as possible to avoid delays.

If you have any questions about our range or would like some advice on the right product for you then please contact us via email at customer.services@nhbs.com or phone on 01803 865913.